Firewire

Cymatic Volcanic Surfboard

Fin System

Size

Cymatic Volcanic Surfboard

Futures / 5'8

Natural Necessity Surf Shop

115 Fern Street

Gerringong NSW 2534

Australia

FEATURES

✓ 5 fin setup (can be ridden as a 5/4/3)

✓ Shape is a hybrid of the Sci-Fi and omni

✓ Double bat tail adds much needed grip to the wave's face, offsetting the extreme lift and speed created by the Quad Inside Single Concave.

✓ Suited to 1-5 feet waves, although surfers who love the 'barely out of control in a fun way' speed will enjoy riding it on head high waves.

RECOMMENDED FINS

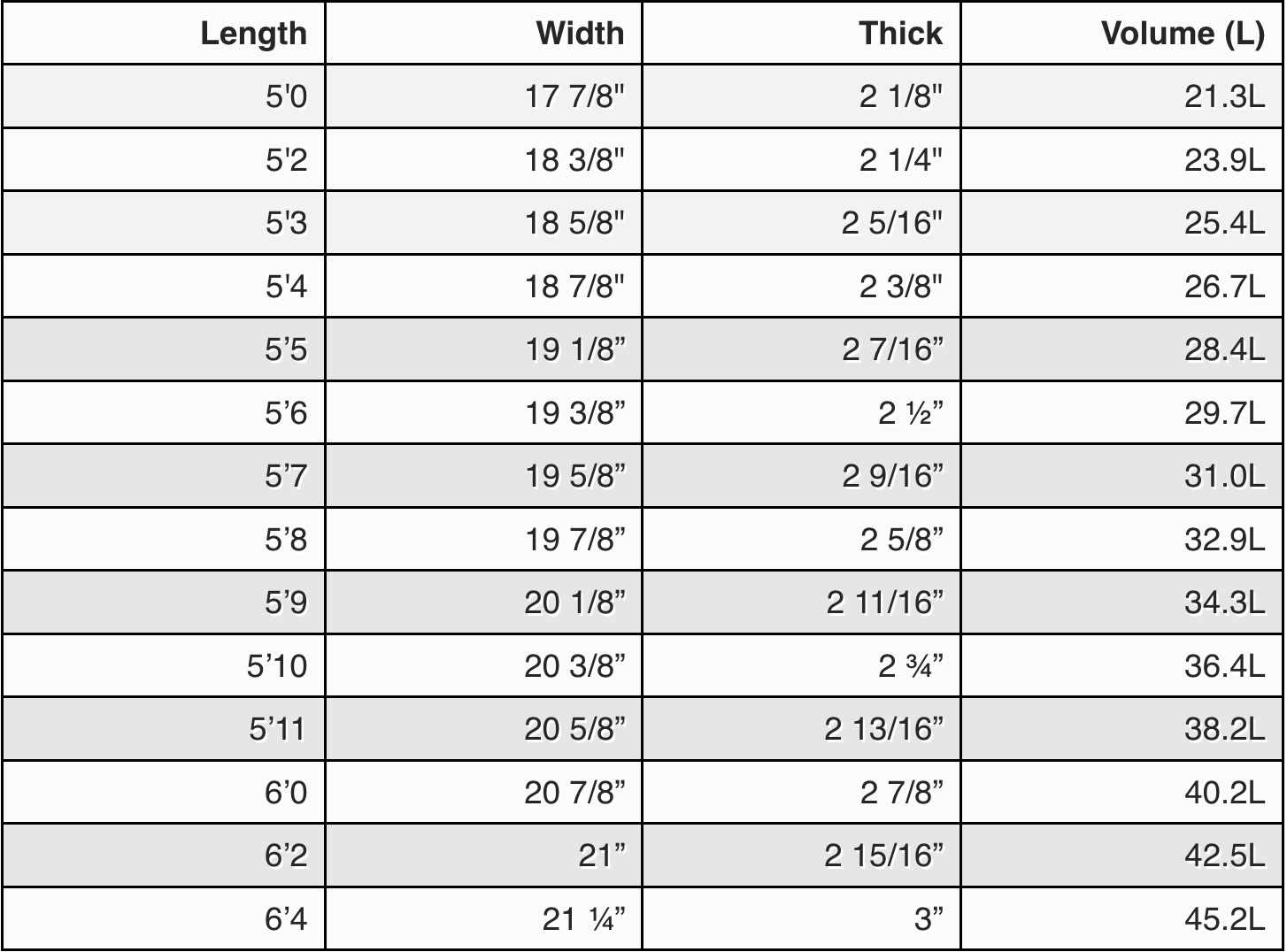

DIMENSIONS

✓ See product images for dimensions

CONSTRUCTION: Volcanic Tech

Volcanic Tech is made from Basalt Fibers Extruded from Volcanic Rocks that are crushed, melted and extruded into woven fibers that make up the cloth. The manufacture of basalt fiber requires the melting of the crushed and washed basalt rock at about 1,500 °C (2,730 °F). The molten rock is then extruded through small nozzles to produce continuous filaments of basalt fiber. Those filaments are then chopped into long stem fibers and woven into lamination cloth fiber. The cloth has similar characteristics to carbon as it relates to strength and weight however because the fibers are derived from Organic Raw materials, when combined with Bio Resins it serves as better degradable ECO alternative than using traditional carbon fiber cloth.

Basalt fiber is a relative newcomer to fiber reinforced polymers (FRPs) and structural composites. It has a similar chemical composition as glass fiber but has better strength characteristics, and unlike most glass fibers is highly resistant to alkaline, acidic and salt attack making it a good candidate for surfboard manufacturing.

Compared to carbon and aramid fiber, it has the features of wider application temperature range -452° F to 1,200° F (-269° C to +650° C), higher oxidation resistance, higher radiation resistance, higher compression strength, and higher shear strength.

The cloth can withstand high temperatures unlike carbon fiber and as a result is heavily used the Aerospace industry in the creation of rockets and and jet engines. The elasticity characteristics of this fiber is higher than that of traditional Carbon fiber allowing the board to have more flex for a natural feel under foot.

QUESTIONS

Not sure what size you should be riding? Check out our Volume Calculator, or get in touch today.

Have a question about the best fins, leash or tail pad to go with this board?

Or can’t find what you’re looking for?

Get in touch about a special/custom order today.

CONCERNS WITH SHIPPING?

If your board is damaged during transit simply send us a photo of the damage, a full front and back photo of the board within 24 hours of delivery, and we can offer to replace, repair or refund your order. For more information see our Shipping page.

ABOUT THE BRAND

Firewire is know for innovating bold new technologies for surfboards that have made them a major player in the surfboard market. In recent years they have taken pride in research and improvements that reduces the impact their industry has on the environment. Originally started by Australian Nev Hyman in 1975, in Perth as Odyssey Surfboards, it became Nev Surfboards in 1981. After travelling Nev decided to pursue creation of blanks for some of the best surfers in the world, and with the years of experience he gained, he began to hone his craft for the perfect surfboard. 17 years later the name was changed again, to Nev Future Shapes, where it entered the global market, manufacturing over 5000 years a year with his growing crew.

Fast forward to 2004, Nev was introduced to Bert Berge who showed him a handmade surfboard featuring balsa rails and high-density composite top and bottom. By 2006 Firewire was officially becoming a global name, with boards generated from CAD/CAM software allowing for the perfect boards to be steadily produced without variations and imperfections in the shape. More recently Firewire has been dedicated and committed to manufacturing boards that will improve your experience with less impact on the environment. In this pursuit they have partnered with BLOOM Foam to develop a traction pad that is the most eco-friendly. After years of growing, developing and honing their craft as a company, they know create boards that cater to all ages and levels of expertise.

“Firewire believes that the combination of EPS/Epoxy and other high tech materials is where the future of surfboard technology lies. Our goal has always been to combine high performance surfing with increased durability resulting in a more sustainable surfboard that increases the fun factor for everyone who rides them. After multiple WSL event wins over the years, and Kelly’s incredible surfing during these last few months of El Nino waves all over the world, we believe in our proven track record for innovative designs and technology. The future under your feet." - Mark Price, CEO

Save 20% off surf accessories with your board purchase.

Discount automatically applies at checkout.

Need a hand with choosing the right gear?

Get in touch!

02 4234 1636

contact@naturalnecessity.com.au

Fast Shipping

Surfboard will be shipping within 1-3 business days.

Tough Packaging

We take great care in packing your new board, to ensure it arrives in brand new condition to you.

Typically this involves a heavy duty box, thick foam or several layers of bubble wrap on the the rails, nose and tail of the board.

Extra buffers at the top and bottom of boards are added.

Boxes are clearly marked as fragile with bright orange fragile tape.

The contents is flagged to our couriers to ensure extra care is taken.

Surfboard Delivery Guarantee

In the unlikely event of your surfboard getting damaged, we have you covered. Each damage is dealt case by case but we can offer

- Refund

- Replacement

- Repair

- Vouchers

Click here for Shipping & Delivery information